Vakmanschap sinds 1981

Bij Breetec draait alles rond vakkennis en maatwerk. We hebben alle tools in handen om zowel stukwerk als totaaloplossingen aan te bieden. Van engineering tot productie en montage; wij garanderen een ijzersterk resultaat. Op vlak van kwaliteit en veiligheid doen we geen toegevingen; onze erkenningen (VCA*, ISO 9001, EN1090, executieklasse 3) zijn daar het bewijs van.

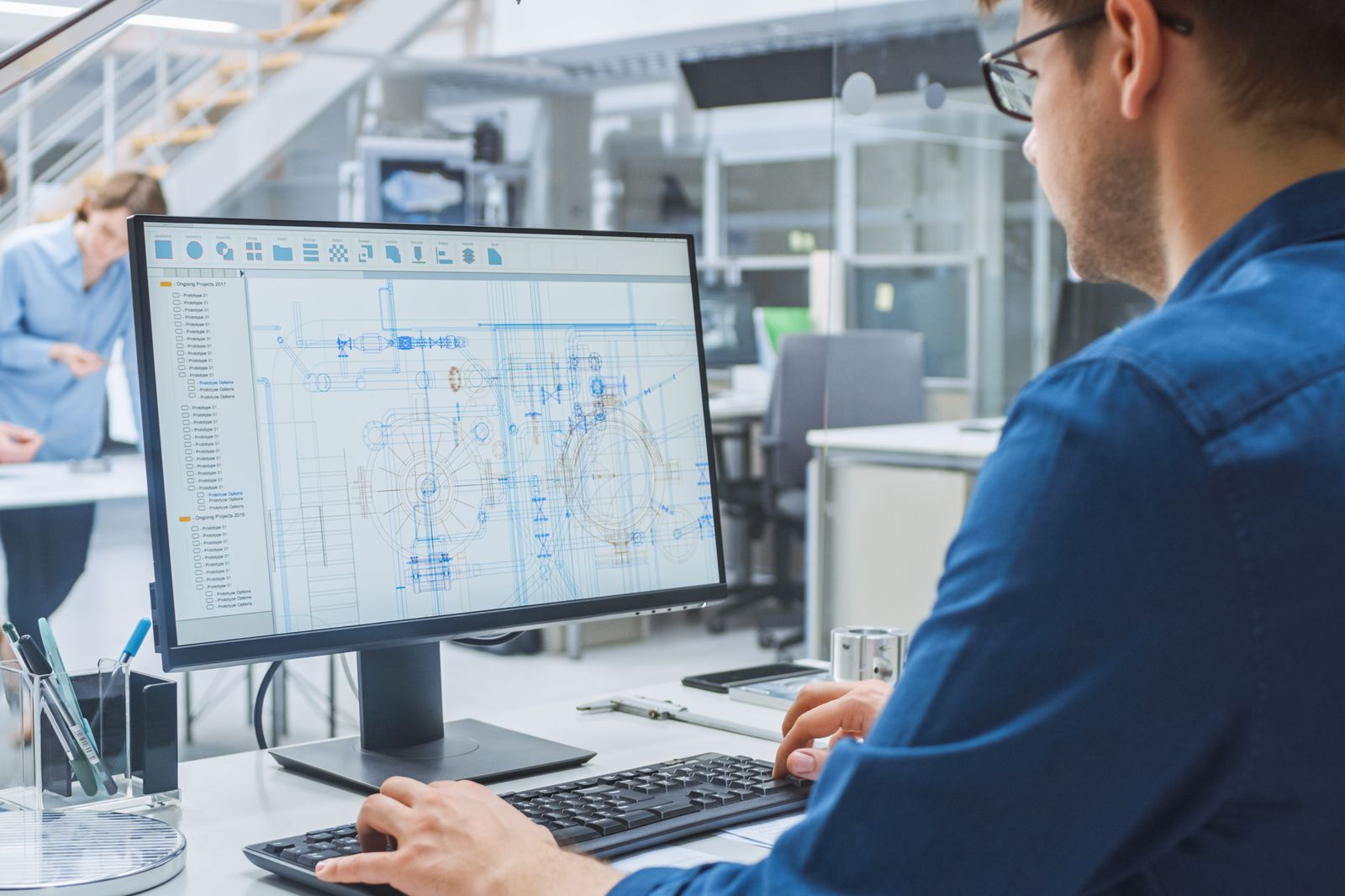

Engineering

Een engineering- en ontwerpteam van het hoogste niveau, dat is wat Breetec zelf in huis heeft. Het geeft ons de mogelijkheid om totaaloplossingen op maat uit te werken, tot in detail en steeds uniek.

Op basis van een schets, idee of een specifiek probleem gaan onze engineers aan de slag. Wij gaan geen enkele uitdaging uit de weg en denken maximaal met u mee. Elk idee zetten we om in ijzersterke realiteit.

Ontdek Meer

Productie

Wij verwerken platen en profielen uit staal, roestvrijstaal en aluminium tot onderdelen, halffabricaten of machinebouw op maat. Zowel voor het fijnere vakmanschap als het robuuste werk bent u bij Breetec aan het juiste adres. Dankzij onze gedegen materiaalkennis en expertise bieden wij een oplossing voor elke technische uitdaging.

Ontdek Meer

Montage & onderhoud

Het assembleren van industriële toepassingen en technische installaties, we doen het graag en goed. Van de montage van trappen, bordessen, loopvloeren, bunkers tot transportbanden, complexe metalen constructies en zoveel meer. Dit kan zowel op de werf als in ons eigen atelier in As. We staan daarnaast ook in voor het mechanisch onderhoud van uw industriële installaties.

Ontdek Meer